How wind turbines work: we explain to you how a wind turbine works to generate electricity from wind. Advantages and disadvantages of windmill generators.

Wind energy has its roots back in ancient times. Already in 3000 B.C., sailors took advantage of wind energy to transport their vessels, equipped with sails that harnessed the wind. In ancient Babylonia, in 2000 B.C., the first windmills were born, used for grinding grains to produce flour.

Today, wind energy is taken advantage of for producing electricity, thanks to the so-called wind turbines; but how do wind turbines work? The working mechanism of a wind turbine is very simple to understand, mostly because of the mechanism’s close relationship to the structure of the wind turbine.

How a Wind Turbine is Made

A wind turbine is composed of a rotating blade that represents the “sail of the system”. The blades act as a barrier that opposes itself to the wind so that the power of the wind forces the blades to rotate, transferring some kinetic energy (energy dictated by the movement) to the blades.

The wind turbines are connected to a rotor, itself connected to the so-called “Tree”, the rotor transfers the mechanical energy (energy of rotation) to the tree, which transmits the energy to the electrical generator that is positioned at the other end of the tree.

A generator is a device that utilizes the properties of electromagnetic induction to produce electric potentials (a difference in electric charge).

To better understand this, it is possible to compare “electric potential” to “pressure”, or a force that moves electricity from one point to another. The generator is composed of magnets and a conductor (a spiral wire). When a conductor is surrounded by magnets and there is a part that undergoes a rotational motion with respect to the rest, we have a generation of a certain amount of potential in the conductor.

In other words, when the wind makes the blades of the rotor turn, the rotor spins the tree, the tree then makes a magnetic structure rotate, transferring energy and generating tension in the coil of wire (the conductor), which produces electrical energy.

In a wind turbine, we can highlight a great number of components. The principle ones are:

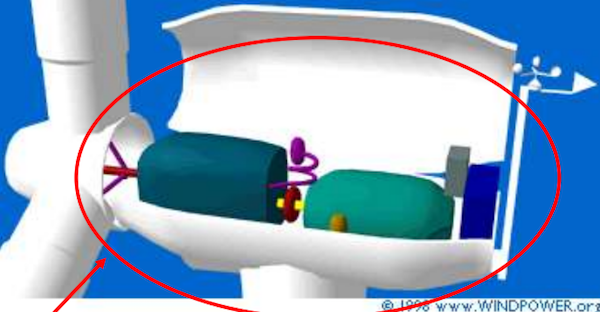

- Nacelle

constitutes the beating heart of the machine; in fact it contains the generator, the gearbox, the brakes, the pitch control actuators, and the yaw control. - Rotor

is constituted by the group of rotating blades, the hub, the tree, and the mechanism of pitch control. - Supporting Tower

plays an obvious structural role in supporting the machine. It serves the purpose of absorbing vibrations generated by the motion of the blades. - Measuring Systems

can be more or less cutting-edge. They capture the direction of the wind, they contain anemometers and other sensors. They are mounted on the uppermost point of the nacelle. On the highest point of the entire wind turbine. Their function is to configure correctly the entire machine according to the intensity and direction of the wind - Control Systems

monitor the correct functioning of the machine and act in case of mechanical failure, putting the whole wind turbine structure in a safe configuration. - Accessory Systems

every manufacturer has different optional systems available. Generally, they allow one to optimize the use of the wind turbine with remote control and management systems, automatic maintenance, elevators to allow access to personnel…

From wind to electricity, here’s how

Essentially, the generator transforms energy of rotation into electrical energy by transferring the energy from one structure to another (from wind to the blades -> rotor -> tree -> generator). This is the working mechanism related to the most simple wind turbine structure. New developments have given birth to more complex wind turbines, but they can all be reduced to the same schematic of energy transfer, which flows from the wind to the blades to the generator.

Wind energy, research

The components previously described are the base that constitute a wind turbine. It is important to clarify that the wind energy sector is in continuous development. The cutting-edge aerodynamics knowledge, the research of new materials, the introduction of more sophisticated control systems… render obsolete the wind turbines built only a few years ago. The most recent systems have rotors that can exceed 100 meters in diameter!

How a wind turbine works

As explained previously, the fundamental working principle of a wind turbine is seemingly simple: the force of the wind puts in motion a series of blades that are connected to a central pivot (hub or rotor). The wind, blowing, makes the blades turn, triggering a rotational motion around the axis of the pivot. Various devices (brakes, multipliers…) are connected to the hub, and transmit the motion generated by the rotating blades to the electrical generator, placed at the base of the tree.

At the center of the workings of a wind turbine is its generator. The generator is the electromagnetic device that allows for the production of electricity from wind. Previously, the generators used for producing wind turbines were of the synchronous type. Today, only asynchronous tri-phase generators are used. How does a wind generator work? The electrical generator of a wind turbine works like any other electrical generator.

As the speed of the wind increases, the instantaneous power generated by the turbine increases, until reaching the nominal velocity (rated wind speed) that allows the wind generator to reach its maximum power (cut-out wind speed). Over this threshold, the wind turbine activates a safety mechanism by which it stops working in order to avoid compromising the machine.

The wind turbine works like any other electrical generator thanks to a gearbox. The gearbox remedies the problem of direct communication between rotor and alternator. When the wind blows strongly, the excessive number of turns of the rotor would continuously trigger the safety mechanism of the generator, interrupting the production of wind energy. The gearbox modulates the power supplied by the generator.

The development of alternators with a high number of polar couples has made it possible to install wind turbines without gearboxes. In this case, the working mechanism is slightly different due to the adoption of ad hoc alternators and gear multipliers. There are still only a few wind turbine producers that have renounced the adoption of gearboxes; nevertheless, the research and development of new turbines seems to be headed in this direction.

Published by Anna De Simone and translated by Raymond Bellon